Lub sijhawm zoo siab tshaj plaws rau cov neeg siv khoom yog thaum lawv tau txaisntoo chippers.Txhawm rau muab cov neeg siv khoom muaj txiaj ntsig zoo siab thiab xyuas kom cov neeg siv khoom tau txais cov khoom siv hluav taws xob zoo li ua tau.Peb lub Hoobkas yuav ua txoj haujlwm zoo ntawm kev kuaj ua ntej xa khoom kom paub meej tias lub tshuab zoo, thiab tom qab ntawd peb yuav ntim lub tshuab nrog cov khoom ntim zoo.

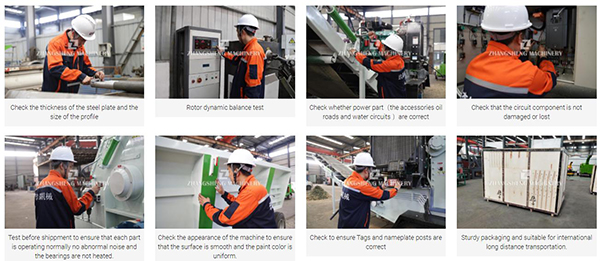

Ua ntej xa khoom, peb muaj kev tshuaj xyuas tshwj xeeb kom ntseeg tau tias cov ntoo chipper yuav tawm hauv lub Hoobkas yam tsis muaj teeb meem.Peb lub chaw soj ntsuam zoo yuav xyuas lub tshuab raws li hauv qab no:

1. Kev tshuaj xyuas qhov tshwm sim: Tshawb xyuas sab nrauv ntawm lub tshuab ua tib zoo kom paub tseeb tias tsis muaj qhov pom kev puas tsuaj lossis hnav.

2. Kev xeem ua haujlwm: Kuaj seb puas muaj ntau yam haujlwm ntawm lub tshuab hluav taws xob ua haujlwm li qub.

3. Kev tshuaj xyuas cov khoom siv hluav taws xob: xyuas tias cov xov hlau tsis zoo, cov khoom siv hluav taws xob nyob hauv qhov chaw thiab txuas zoo.

4. Hydraulic system soj ntsuam: Tshawb xyuas qhov kev hloov ntawm cov roj hydraulic, kev huv ntawm cov lim, thiab qhov nruj ntawm cov kav dej thiab kev sib txuas.

5.Trial run: Ua ib qho kev sim khiav ntawm lub tshuab kom pom tias muaj suab nrov txawv txav, kev co lossis roj to.Xyuas kom tseeb tias cov ntoo chipper tuaj yeem ua haujlwm ruaj khov thaum khiav.

6. Kev tshuaj xyuas kev nyab xeeb: xyuas seb cov khoom siv kev nyab xeeb ntawm lub tshuab puas ua tiav thiab nyob rau hauv qhov zoo, thiab ua raws li cov qauv kev nyab xeeb.

7. Txheeb xyuas cov ntaub ntawv thiab cov khoom siv ntxiv: Xyuas seb cov ntaub ntawv thiab cov khoom siv tau ua tiav.Xyuas kom tseeb tias koj muaj lub tshuab tus tswv phau ntawv, phau ntawv qhia kev pabcuam, thiab cov khoom seem thiab cov cuab yeej tsim nyog.

Tom ntej tsab xov xwm peb yuav qhia koj li cas peb ntim peb cov khoom, Nyob twj ywm!

Txhua yam lus thiab cov lus nug los ntawm koj yuav tau txais txiaj ntsig zoo, ua tsaug, kuv tus phooj ywg.

Post lub sij hawm: Dec-13-2023